As one of the world’s top three comprehensive rock drilling machine manufacturers, our tunnel drill jumbos hold an overwhelming share of the domestic market. We rise to the challenge of any and all tunnel excavation projects, including highways and bullet trains, thereby contributing to domestic and international infrastructure development by incorporating the latest technology.

Tunnel Construction

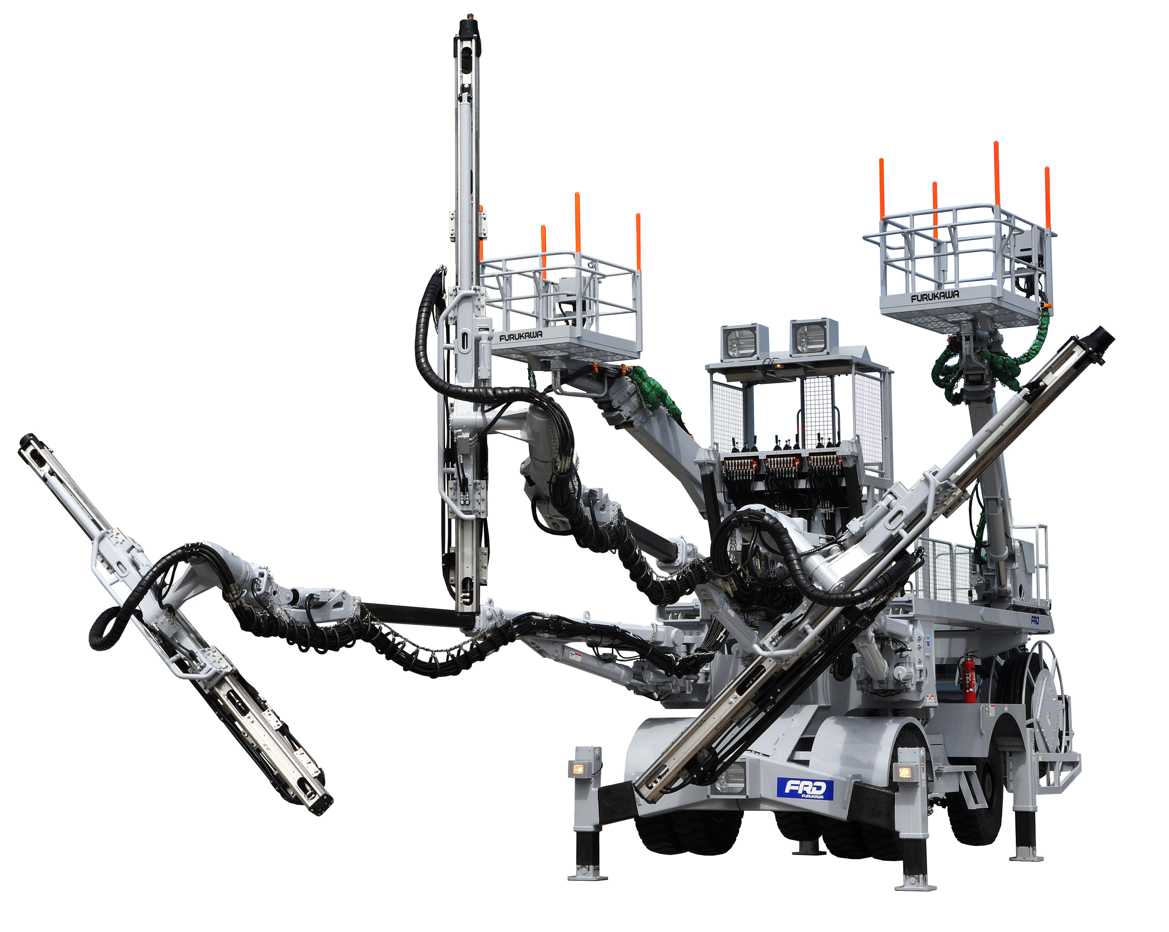

We develop and design various proprietary components, including the cutting-edge HD250 hydraulic drifter. We offer a wide range of drill jumbos tailored to customer specifications, from medium to super-large cross-sectional tunnels.

Drill Jumbos

Features

-

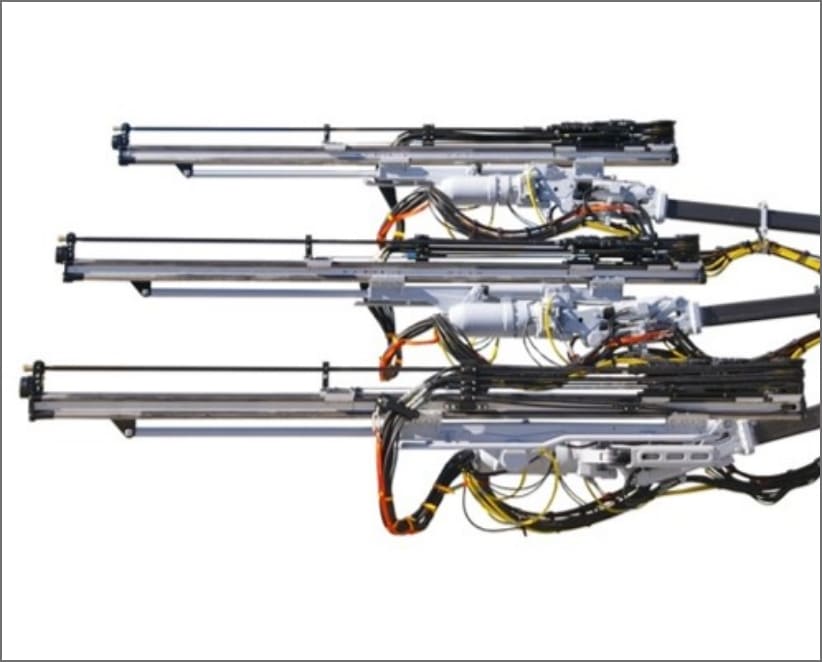

Light Aluminum Sigma Type Guide Shell

Features a high-strength aluminum Σ-shaped guide shell resistant to bending and torsion, with improved dust and abrasion resistance, improved sliding surface lubricity, and mortar adhesion resistance.

-

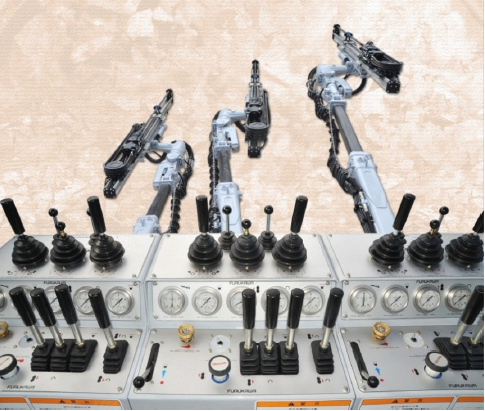

Drilling and boom/guide shell control

The functional operation lever mounted on the operator deck that rises diagonally forward enables speedy drilling work.

-

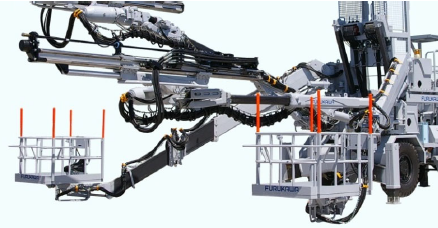

Working Cage

Equipped with cage parallel tuning mechanism and cage swing mechanism as standard.

Can be moved to the working face and side wall at the optimum position.

For Medium Cross-Sections

-

JTH2100A(2-boom, 1-cage)

For Large Section/Super Large Section

-

JTH2100R(2booms、1cage)

-

JTH2200R-III(2booms、2cages)

-

JTH3200R-III(3booms、2cages)

Mining

FRD designs and develops small section wheel drill jumbo and fan cut drills to meet mining needs. FRD has been highly praised at mining sites both in Japan and overseas.

Drill Jumbos

-

T1AM

T2AM

Equipped with the HD220 Hydraulic Drifter. Simplified hydraulic control circuits streamline maintenance and repair work. Achieves a maximum climbing speed of 8 km/h on 7-degree inclines, reducing tunnel travel time.

Fan Cut Drill

-

FTH1AM-709

Features a boom and rod changer enabling versatile positioning. It is a reliable mid-size long-hole drilling machine equipped with the proven HD709 hydraulic drifter.

| Model | JTH2100A | |

|---|---|---|

| Drilling coverage | mm | W9,600 x H6,600 |

| Number of boom | 2 | |

| Number of charging cage | 1 | |

| Drifter model | HD220 | |

| Number of percussion | min-1 | 2,900~3,800 |

| Hole diameter | mm | φ45~76 (φ102) |

| Model | JTH2100R | |

|---|---|---|

| Drilling coverage | mm | W12,770 x H8,490 |

| Number of boom | 2 | |

| Number of charging cage | 1 | |

| Drifter model | HD220 | |

| Number of percussion | min-1 | 2,900~3,800 |

| Hole diameter | mm | φ45~76 (φ102) |

| Model | JTH2200R-III | |

|---|---|---|

| Drilling coverage | mm | W12,770 x H8,490 |

| Number of boom | 2 | |

| Number of charging cage | 2 | |

| Drifter model | HD220 | |

| Number of percussion | min-1 | 2,900~3,800 |

| Hole diameter | mm | φ45~76 (φ102) |

| Model | JTH3200R-III | |

|---|---|---|

| Drilling coverage | mm | W13,220 x H8,840 |

| Number of boom | 3 | |

| Number of charging cage | 2 | |

| Drifter model | HD220 | |

| Number of percussion | min-1 | 2,900~3,800 |

| Hole diameter | mm | φ45~76 (φ102) |

| Model | T1AM | T2AM | |

|---|---|---|---|

| Drilling coverage | mm | W5,850 x H5,370 | W6,185 x H6,420 |

| Number of boom | 1 | 2 | |

| Number of charging cage | – | – | |

| Drifter model | HD220 | HD220 | |

| Number of percussion | min-1 | 2,900~3,800 | 2,900~3,800 |

| Hole diameter | mm | φ45~76 (φ102) | φ45~76 (φ102) |

| Model | FTH1AM-709 | |

|---|---|---|

| Drifter model | HD709 | |

| Number of percussion | min-1 | 2,250~2,500 |

| Hole diameter | mm | φ64~89 |

| Rod changer | ||

| Rod length | mm | 1,220(T38-MF rod) |

| Number of rod | pcs | 21 |