Blast Hole Drills are self-propelled machines that drill downward (creating holes in rock) to charge explosives for blasting. Collectively referred to as Blast Hole Drills, they encompass crawler drills, down-the-hole drills, and rotary drills. In open-pit excavation sites like mines and quarries, Bast Hole Drills create holes to blast rock and extract stone. Used widely in Japan and overseas, they contribute to the mining of crushed stone and limestone (raw materials supporting infrastructure development), non-ferrous metals (gold, silver, etc.), and iron ore. The amount of explosives used varies depending on the size of the drilled hole, which in turn affects the quantity of rock produced after blasting. Since the size of the Blast Hole Drill depends on the diameter of the hole that is needed, consider the production scale when selecting the appropriate size.

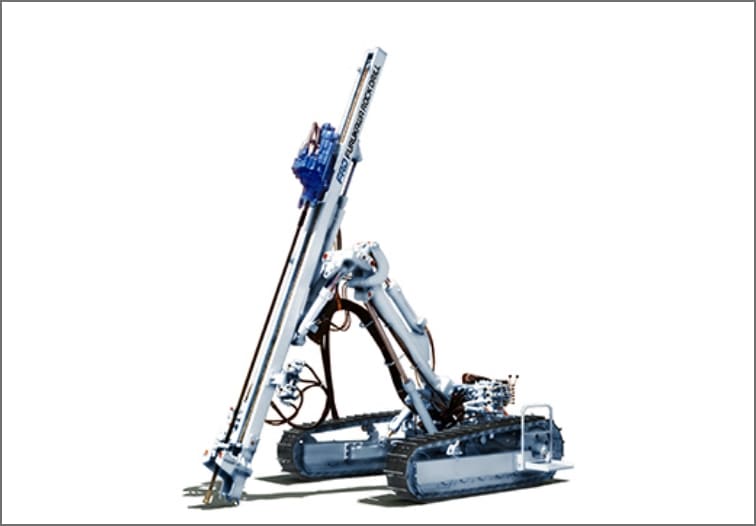

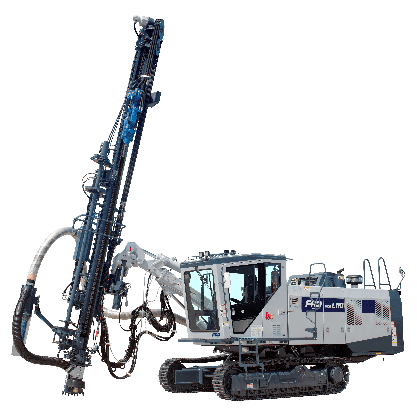

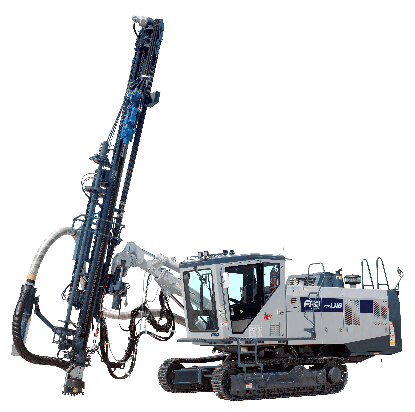

Hydraulic Crawler Drills

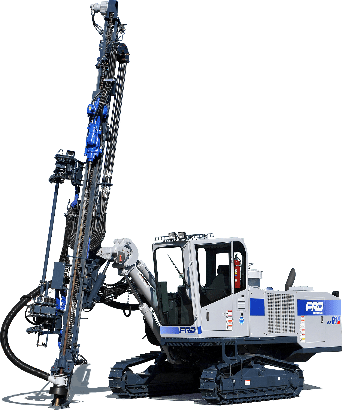

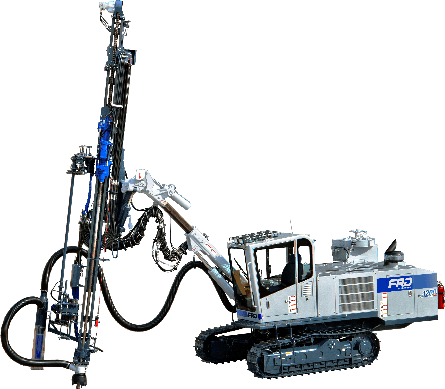

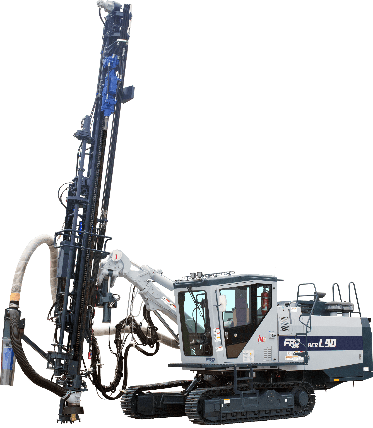

In 1977, we developed Japan’s first hydraulic crawler drill. It has since undergone model changes and has expanded into the HCR Series of hydraulic crawlers, which are used by customers both in Japan and overseas.

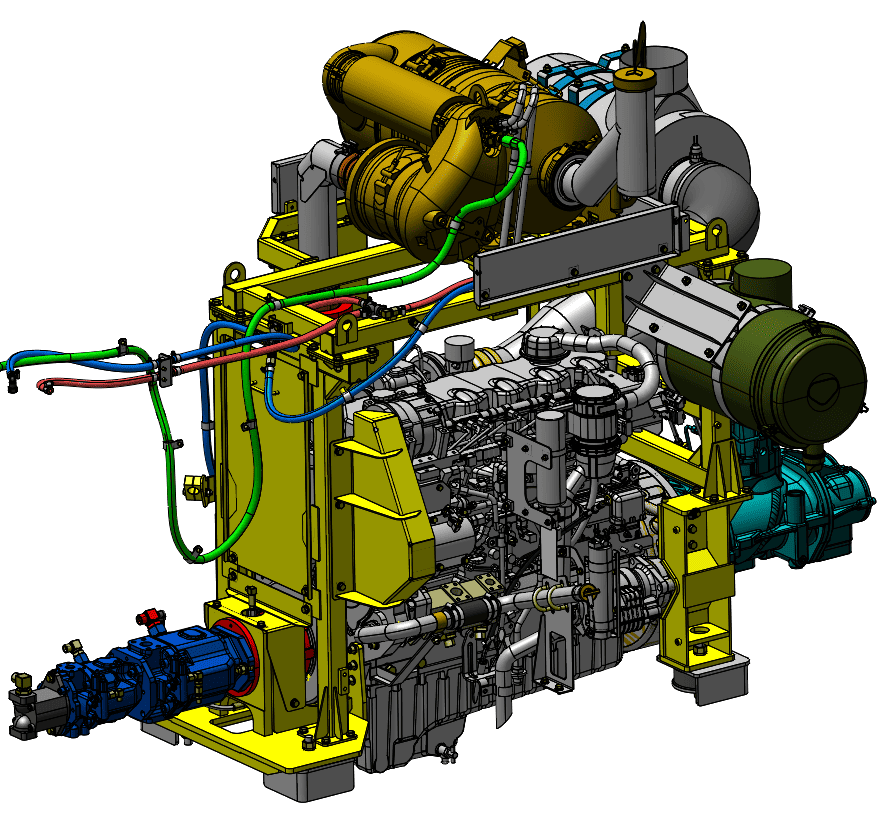

The latest lineup features the HD800 Series Drifter. By maintaining optimal drilling conditions in response to constantly changing rock conditions, this drill easily enables accurate, speedy drilling with minimal hole deviation.

Features

-

iDS (Intelligent Drilling System)

iDS automatically controls drilling to maintain optimal conditions regardless of changes in the rock quality, supporting smooth drilling.

-

iMS

(Inteligent Monitoring System)Monitors and centralizes the display of machine operating status and maintenance information.

(Image shows HCR110, HCR L90 & HCR L90s) -

Reduced fuel consumption

Features an eco-friendly clean engine. The Super Economy Mode PLUS function reduces fuel consumption while maintaining drilling performance.

Engine: Tier 3

-

HCR910-DSHole diameter 64~89mm

Tier 3

Tier 3 -

HCR1200-DSIIIHole diameter 76~115mm

Tier 3

Tier 3 -

HCR1200-EDSIIIHole diameter 76~115mm

Tier 3

Tier 3 -

HCR L100-E3Hole diameter 89~127mm

Tier 3

Tier 3 -

HCR L100-L3Hole diameter 89~127mm

Tier 3

Tier 3 -

HCR L110-E3 (HD836)Hole diameter 102~140mm

Tier 3

Tier 3

Engine: Tier 4 final/Stage V

-

HCR A70-2-F5Hole diameter 64~89mm

Tier 4final/

Tier 4final/

Stage V -

HCR900-ESVHole diameter 64~89mm

Tier 4 final

Tier 4 final -

HCR1100-ERHole diameter 64~102mm

Tier 4 final

Tier 4 final -

HCR L90s-E5Hole diameter 76~115mm

Tier 4final/

Tier 4final/

Stage V -

HCR L90-E5Hole diameter 76~127mm

Tier 4final/

Tier 4final/

Stage V -

HCR L110-E5 (HD828)Hole diameter 102~127mm

Tier 4final/

Tier 4final/

Stage V -

HCR L110-E5 (HD836)Hole diameter 102~140mm

Tier 4final/

Tier 4final/

Stage V

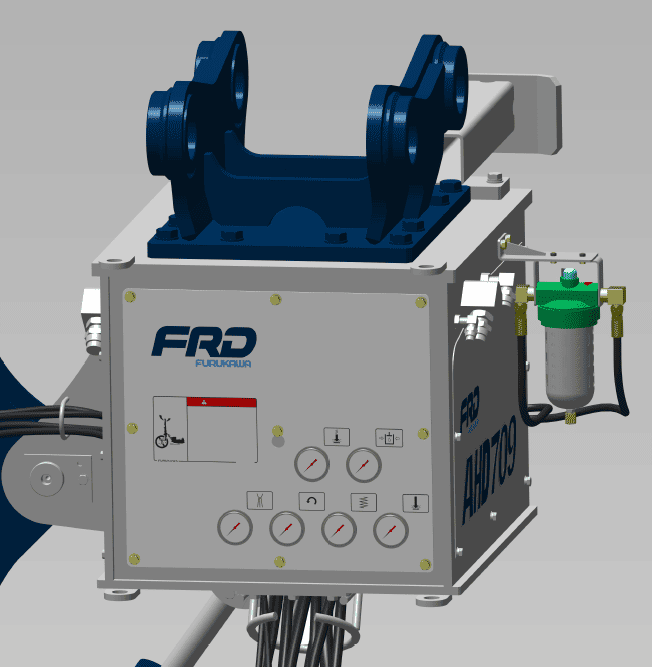

Attachment Drill (AHD709)

It is an attachment drill that can be attached to hydraulic excavators. If customer wants to increase drilling efficiency at a site where a pneumatic drill is used, or if a bench is not stable at the initial development of a stone quarry, drilling can be performed over a wide area. Equipped with the proven HD709 drifter.

Features

-

Powered by FRD HD709 Hydraulic Drifter

-

All hydraulic equipment is housed in the attachment drill box and receives oil pressure from the hydraulic breaker piping.

-

Drilling is performed by a wired controller. The controller is lightweight and simple to operate.

Products

-

AHD709

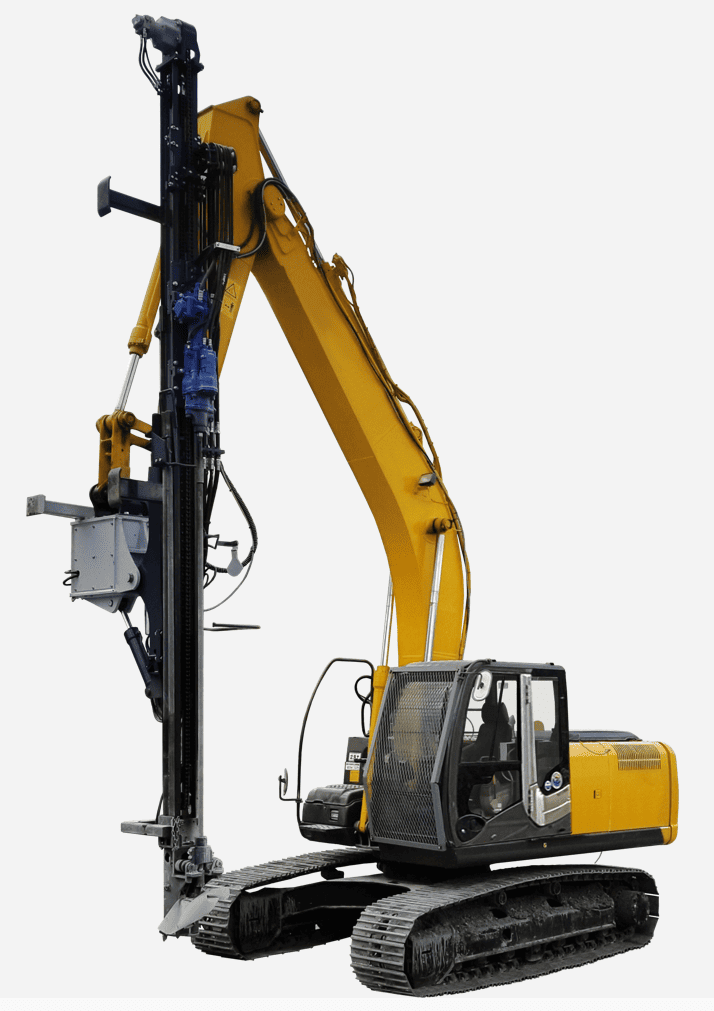

Down The Hole Drills

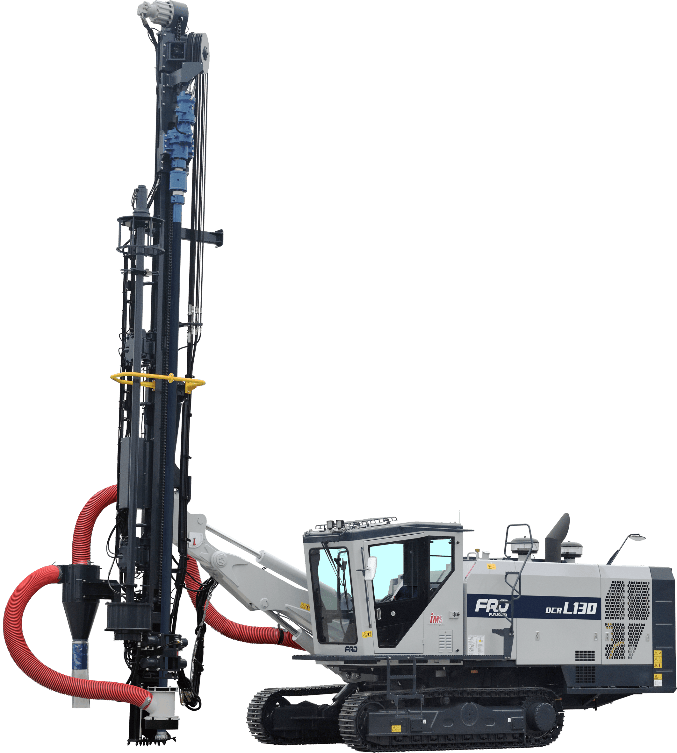

A Down-the-Hole Drill is a machine that uses a down-the-hole hammer to drill larger blast holes than crawler drills. It is used in large-scale limestone mines and similar applications.

In addition to excellent drilling capability, this drill excels in mobility, operability, durability, cabin comfort, and maintainability.

Features

-

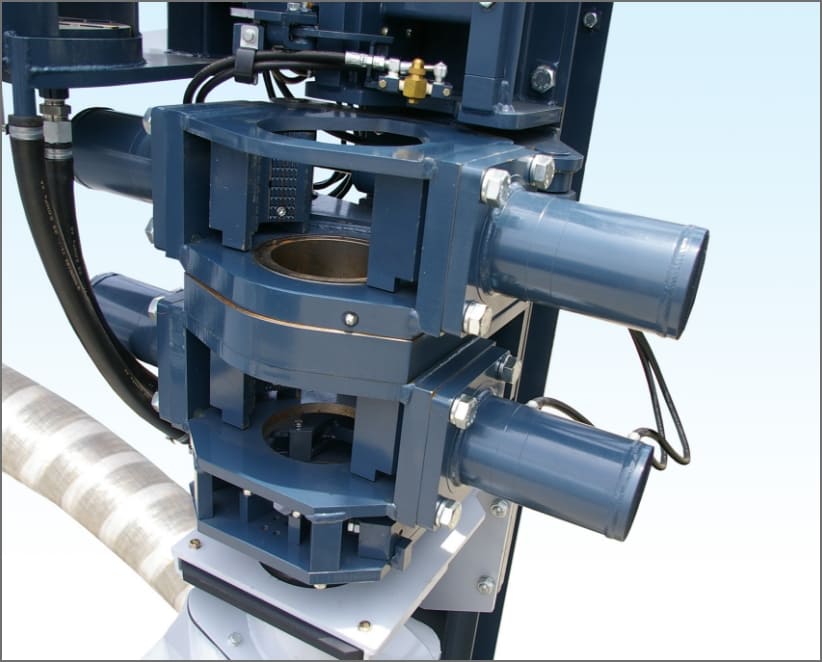

The lever operation is similar to a hydraulic crawler drill, and drilling is possible with a simple lever operation. (Photo: DCR L130 F5)

-

Rod changing and loosening can be performed with simple lever controls. (Photo: DCR20)

-

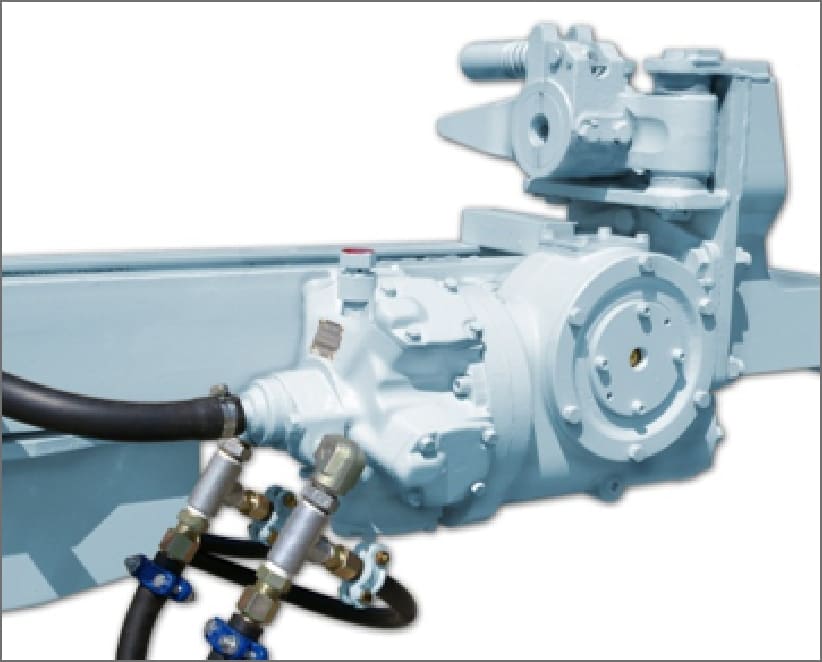

The heavy-duty rotary head enables speedy and powerful drilling. (Photo: DCR20)

Products

-

DCR20

Tier

Tier -

DCR L130-F5

Tier 4final/

Tier 4final/

Stage V

Pneumatic Crawler Drill

A robust, low-maintenance pneumatic crawler drill equipped with a high-performance pneumatic drifter. A long-selling model with enduring popularity overseas.

Features

-

High-performance, noise-reducing PD200 drifter

Features a piston shape that enables ideal transmission of impact force, minimizing performance degradation even during long-hole drilling.

Capable of drilling across a wide range of rock types, from soft to hard rock. -

Powerful box structure, exhaust silencer guide shell

Features a robust box-shaped structure with an exhaust silencer for the drifter. The centralizer has a sturdy design enabling rod replacement without using rod clamps.

-

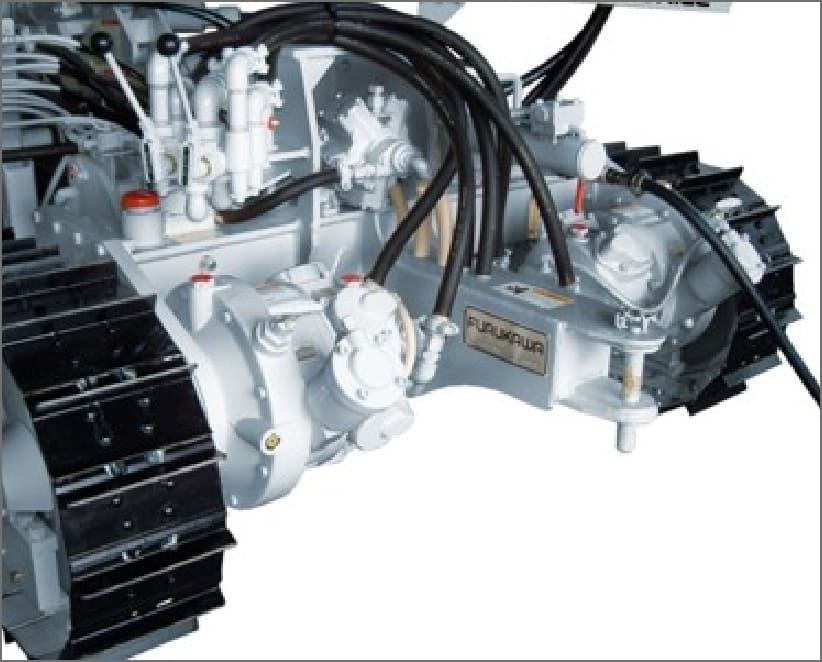

Robust undercarriage with easy daily maintenance

A powerful undercarriage that utilizes bulldozer components. The front idler and track rollers are self-lubricating.

Products

-

PCR200