Hydraulic breakers are mounted on hydraulic excavators and are used for excavation of rock, secondary breaking, and crushing of concrete.

Furukawa Rock Drill’s hydraulic breakers contribute to global infrastructure development by offering a diverse lineup of small to ultra-large models for bedrock excavation, meeting customers’ diverse needs.

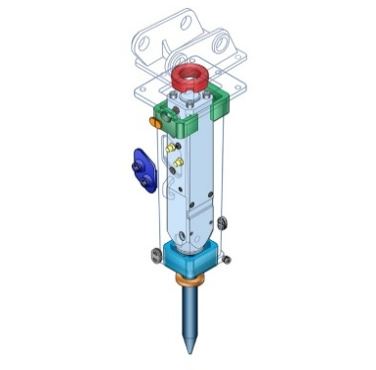

Hydraulic Breaker Fx-α(Alpha) Series

(Recommended carrier weight 0.85-5.5 tons)

The advanced Small Hydraulic Breaker Fx Series enable optimal matching with high-power mini excavators.

Their simple, No through-bolt structure and breaker body design based on vibration mode analysis achieve low noise and low vibration in standard models.

A wide selection of brackets tailored to specific works is another key feature.

The lineup naturally includes the ultra-low noise ST-Box specification model.

Features

-

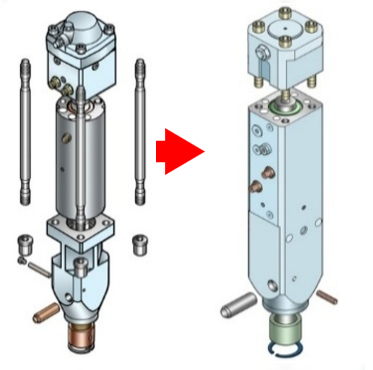

Monoblock and thru-boltless make thru-bolt maintenance unnecessary and contribute to low noise and vibration.

-

The breaker body is housed in a bracket with a closed box frame structure, and is held by a damper to achieve low noise and low vibration.

-

Two types of brackets, bracket type and T-Box type, are available to match various mini excavators.

Hydraulic Breaker F6, F9 (Recommended carrier weight 5.5~9 ton)

It is a multi-medium hydraulic breaker that can be mounted on hydraulic excavators and large oil-based Back Hoe Loaders.

Features

-

The use of a large diameter piston and accumulator has realized stable high impact force.

-

Low noise bracket T-BOX and Back Hoe Loader special bracket are available for mounting on hydraulic excavator and Back Hoe Loader.

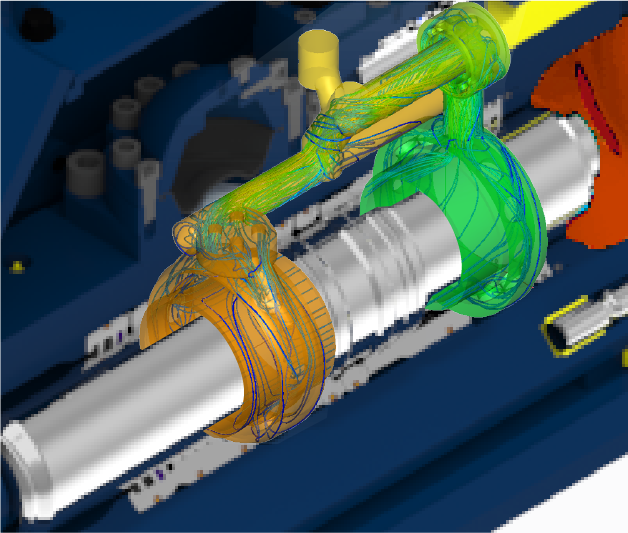

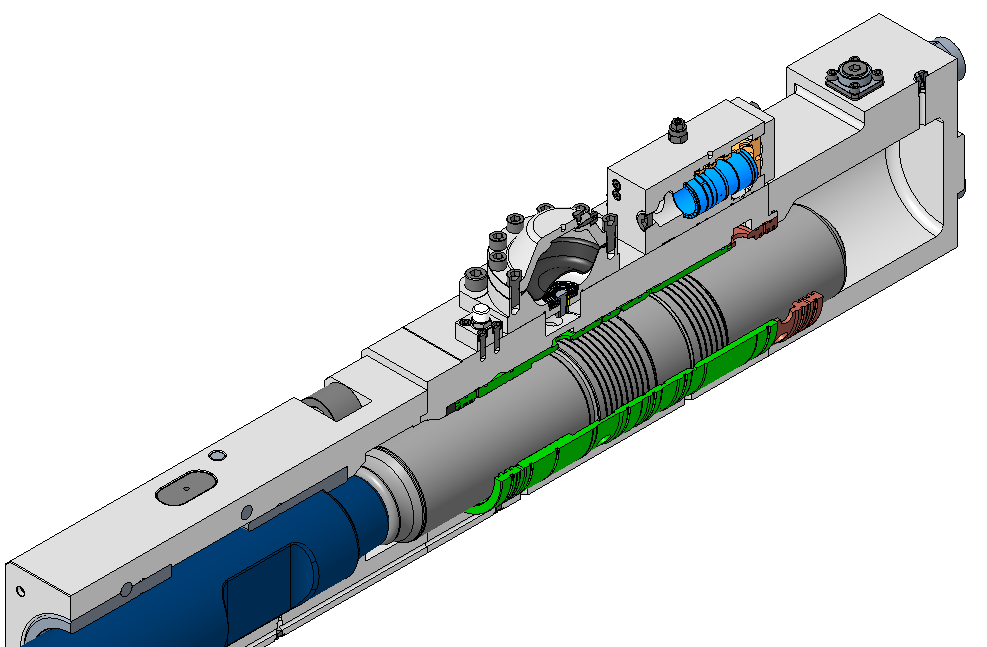

Hydraulic Breaker FHB Series (Recommended carrier weight 9~52 ton)

By further advancing the world’s leading monoblock type hydraulic breaker, we have realized high durability, high crushability, high maintainability, and low noise at a high level to provide customers with comfort, peace of mind, and excellent service. In addition, we have introduced environmental load reducing elements that further improve operating efficiency and reduce the engine load of hydraulic excavators.

Features

-

Three-dimensional fluid analysis has been used to reduce hydraulic resistance inside the breaker and improve impact force. This reduces work time and reduces the load on the engine, reducing CO2 and reducing environmental impact.

-

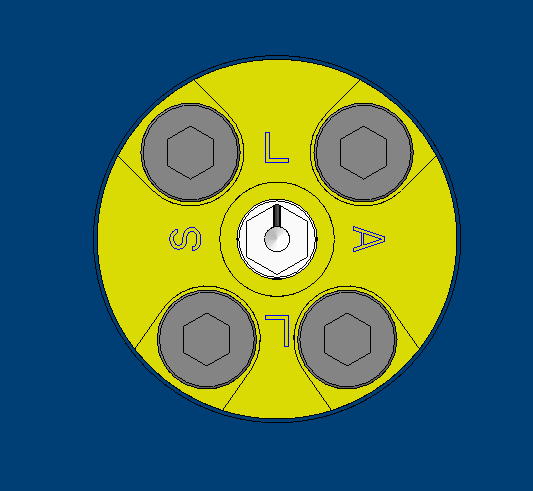

The QUICK SWITCH VALVE (QSV) allows easy adjustment of the stroke. By simply turning the QSV 90°, it is possible to switch between Short Stroke (S), Long Stroke (L), and Blank Prevention Mode (A).

-

*Optional SMART STROKE SYSTEM (SSS) automatically adjusts stroke length of the piston. Reduces excess operating energy due to impact after crushing and reduces damage to the hydraulic breaker body.

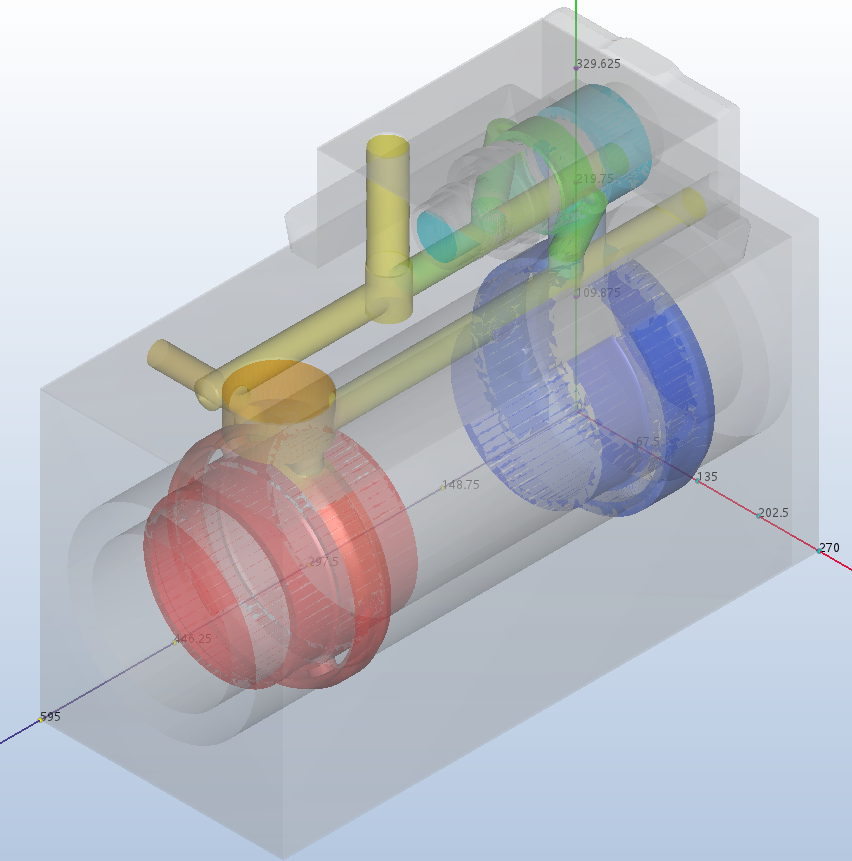

Hydraulic Breaker Fxj770α(Alpha), Fxj1070α(Alpha)

(Recommended carrier weight 44~110 ton)

This ultra-large, ultra-low noise hydraulic breaker combines overwhelming crushing power with high durability. Its powerful crushing force and high versatility prove effective in urban civil engineering and plant demolition.

Features

-

By improving efficiency through fluid analysis, it has achieved the largest impact power in its class. The same input has increased impact power.

-

The cylinder liner structure improves piston centering performance and reduces maintenance costs.

-

Equipped with auto grease as standard. Optimum grease supply contributes to improving the life of consumables in the front.