The Hydraulic Crusher V Series is used widely in low-pollution (low noise, low vibration) demolition methods, ranging from crushing aged concrete buildings and reinforced structures to processing secondary concrete products and separating/recovering rebar.

The development of the Hydraulic Crusher V Series was based on the fundamental principles of people-friendly and eco-friendly crushers that are lightweight, fast, and powerful.

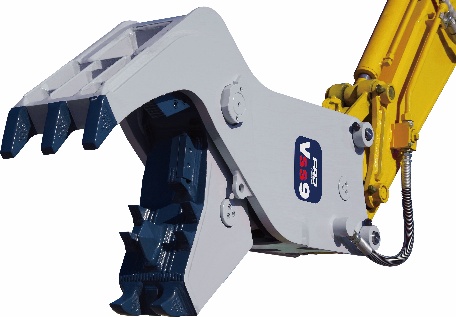

Secondary Crusher Vs Series

Used primarily for secondary crushing, breaking down of concrete, and sorting work, such as separating and recovering concrete debris from rebar.

Features

-

Experience the Lightness! Enables Quick Operation

The trunnion-type hydraulic cylinder and compact body length enhance operability.

-

Large Teeth Enable Powerful Crushing

The large wedge-shaped center teeth allow for powerful impact crushing, and the side teeth release crushing.

-

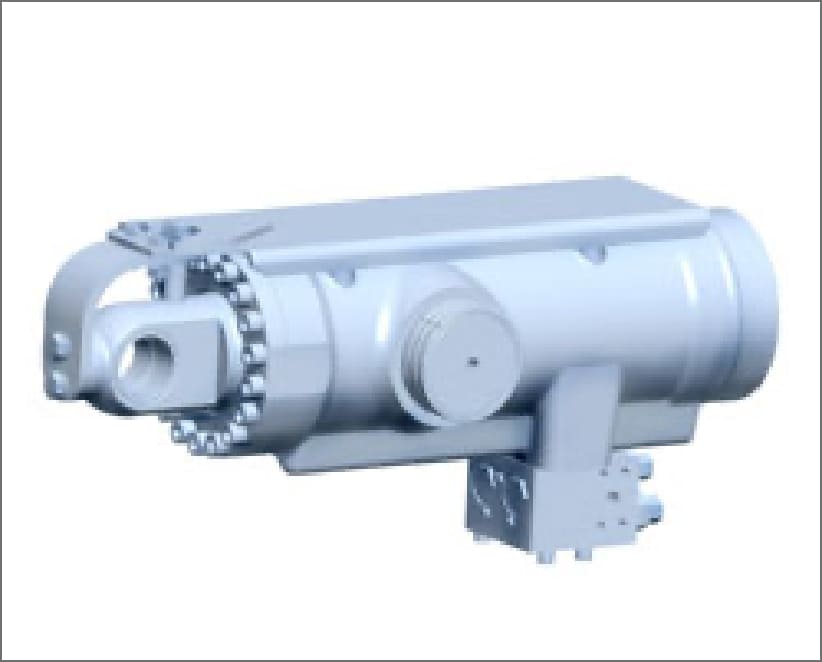

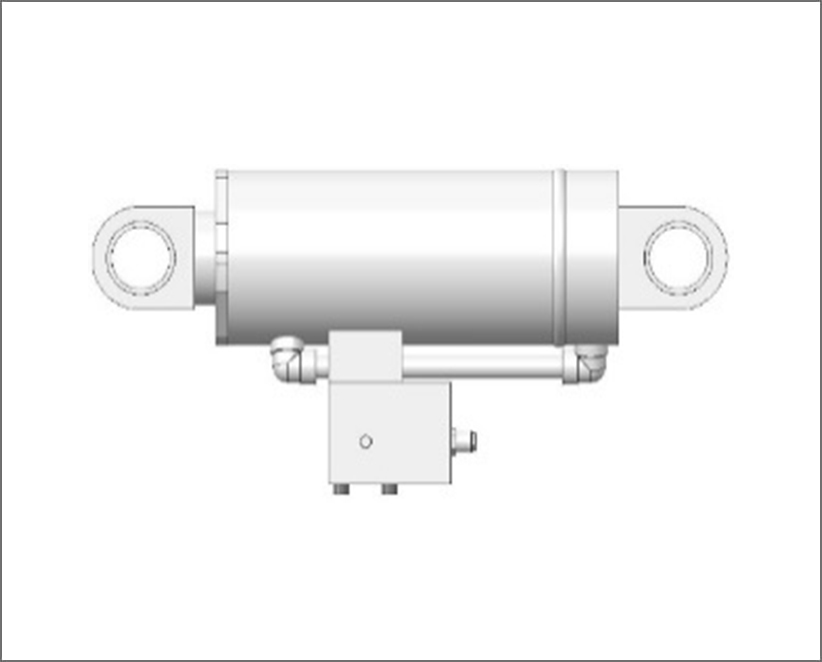

High-Output Trunnion-Type Hydraulic Cylinder

The powerful trunnion-type compact hydraulic cylinder allows for trackable and powerful crushing.

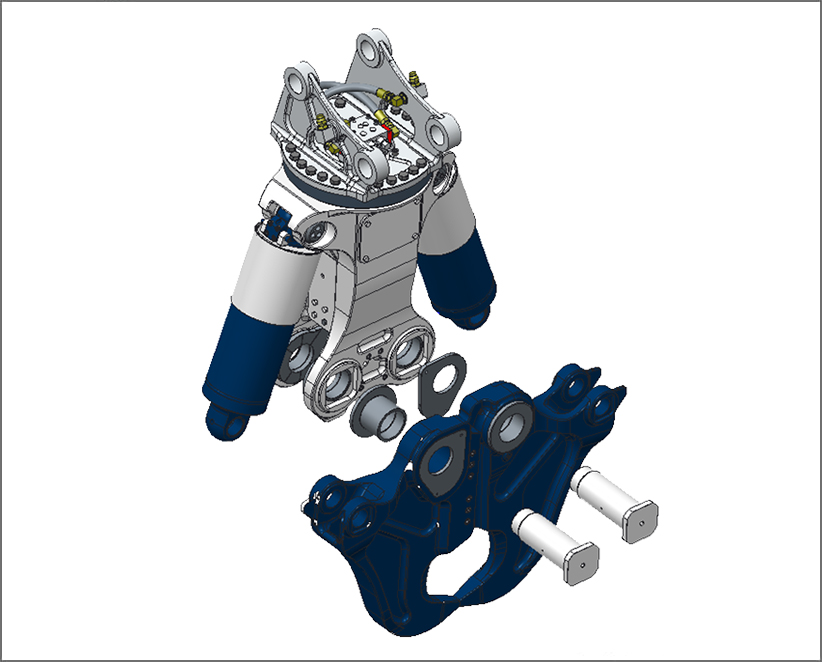

Secondary Crusher Vss Series

Used primarily for secondary crushing, breaking down of concrete, and sorting work, such as separating and recovering concrete debris from rebar.

The Vss15 is a versatile machine compatible with a wide range of 10-20 ton hydraulic excavators, enhancing excavator utilization rates.

Features

-

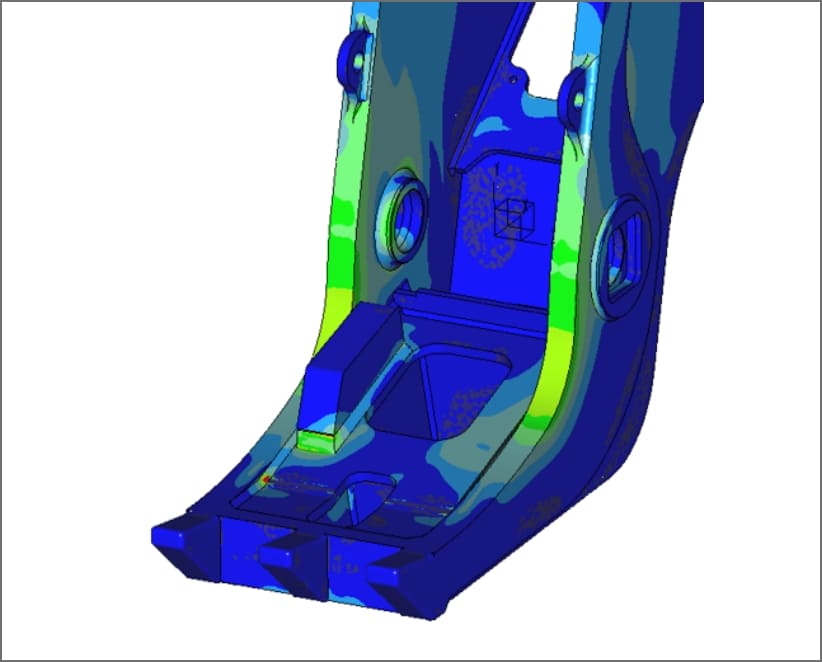

Robust Box-Structure Frame

An optimized, durable frame structure featuring enhanced wear resistance and improved durability through 3D structural analysis.

-

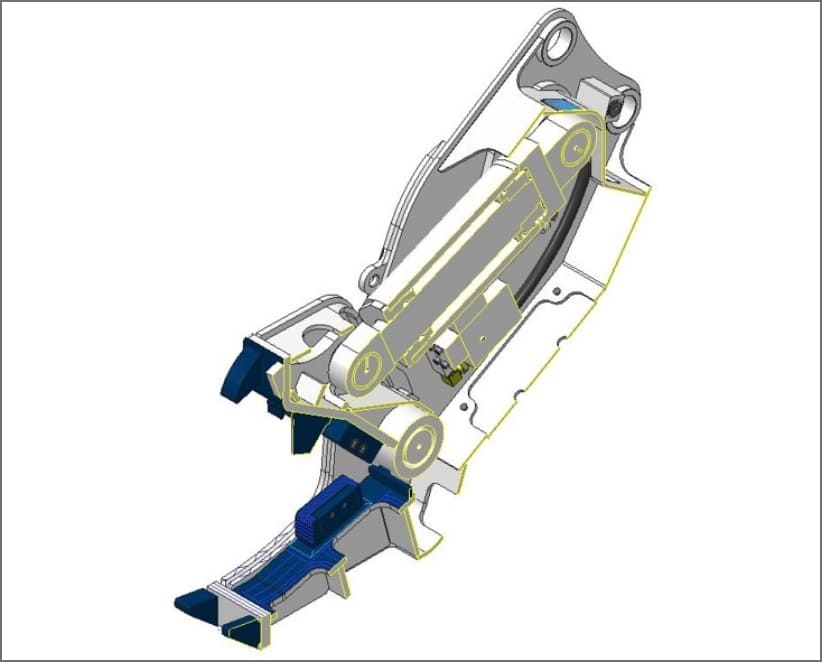

Smooth-Operating Hydraulic Cylinder

Features a double-ended clevis cylinder, minimizing stress on hoses and cylinder connection points.

-

High speed valve is equipped as standard.

The high-capacity, high-speed valve enables rapid closing of the active frame.

Primary Crusher Vx Series

Used primarily for crushing and breaking concrete columns, beams, foundations, and crossbeams during building demolition.

Also used for dismantling revetments and bridge piers, making it suitable for demolition work in urban areas.

Features

-

Superlight yet Robust Body

A lightweight, robust body with excellent visibility.

-

Dual-Cylinder System

Features inverted high-output cylinders with powerful crushing force, stable lateral balance, and a high-speed valve (standard) for faster closing speed. (Vxs18 is a single-cylinder type)

-

Hoe-shaped Arm

Features a long and wide bucket, plus a wedge-shaped cutting edge for excellent penetration into target materials.

Multi Crusher Vz Series

A hydraulic primary crusher for demolishing steel-reinforced concrete (SRC) structures.

Used for demolition in urban redevelopment, large-scale plant demolition, and demolition of aging infrastructure.

Features

-

Maximum Crushing Force

Achieves the foremost opening width and tip crushing pressure of its class through optimally positioned center pin and inverted high-output cylinders.

-

Prevents gaps in the cutter

Adapts a mechanism to maintain the gap between the cutters.

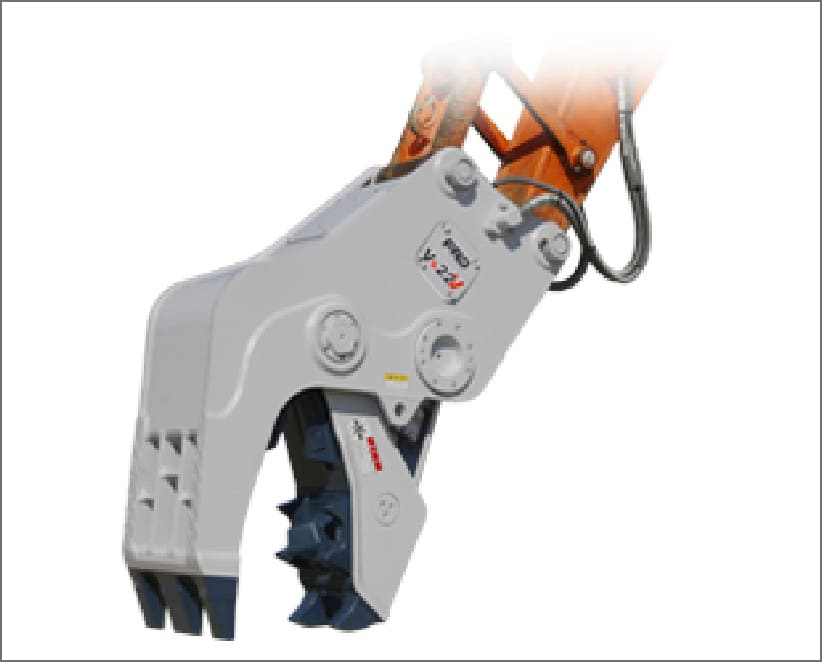

Combi Cutter / Crusher Vc Series

Steel cutters are used mainly for dismantling steel structures.

Since no gas cutting is required, these steel cutters enable safe and highly efficient dismantling.

They handle everything from crushing concrete structures to cutting heavy steel materials.

Features

-

Enhanced Cutting Performance with a Robust Body

Improved operational performance through a slim beak-shaped frame with a wide opening.

-

Integrated Center Tooth

The large wedge-shaped teeth mounted in the center of the tip enable powerful crushing.

(Applicable Models: Vc22, Vc15, Vc9) -

Ultra-Slim Frame with a Super Slim Tip

Features a large-diameter center pin to maintain a sharp cutting edge, and a lightweight, tough frame.