Crawler Drill Drifter

Featuring a dual damper mechanism that automatically detects and controls changes in drilling conditions, and a wedge-shaped piston design for optimum energy transfer efficiency, it quickly adapts to a wide range of rock types. By providing optimal control based on load, it achieves high fragmentation efficiency. Allows for stable, comfortable, and efficient drilling without any need for complex operations.

Features

-

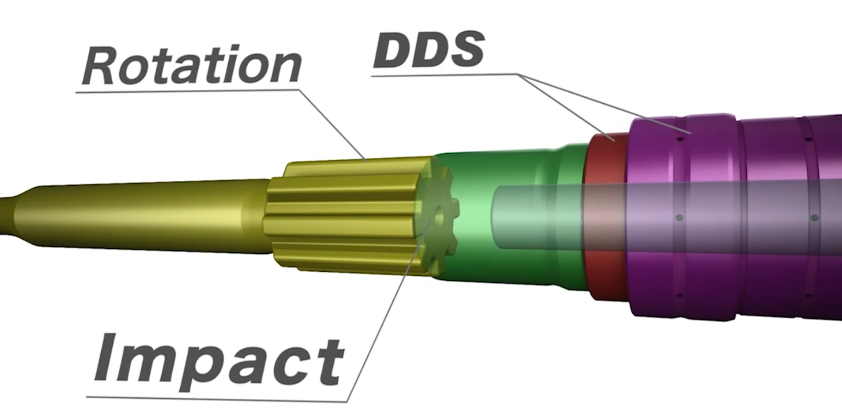

Wedge-shaped piston

Through computer simulation and field testing, this shape was determined to deliver the most efficient impact performance.

-

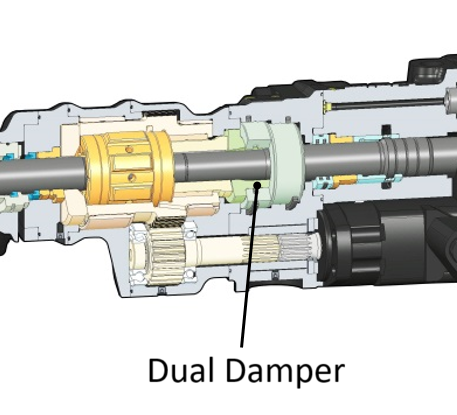

Dual Damper

The dual damper maintains rock contact and absorbs rebound force from the rock mass. By optimizing the efficiency of impact energy propagation, it enhances drilling capacity and product life.

-

Reverse Percussion (Optional Equipment)

This device forcibly pulls out the rod when jamming occurs. It enables smooth rod extraction, minimizing the stress of drilling.

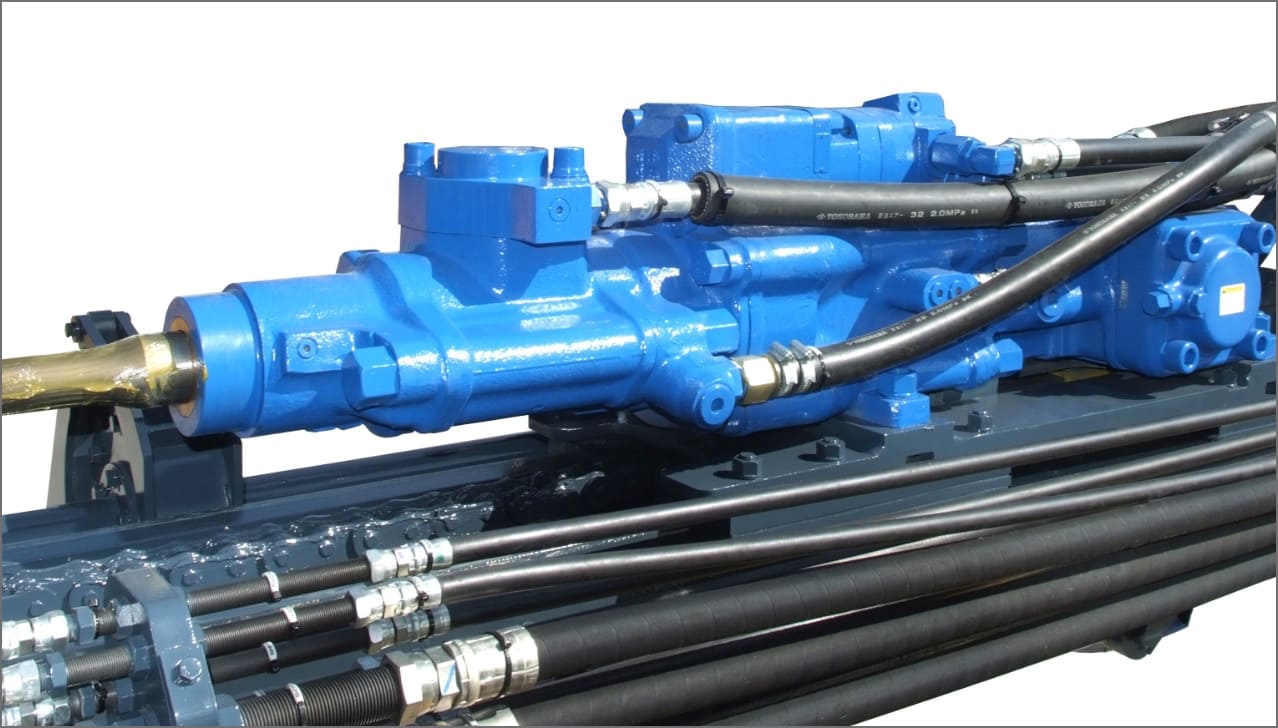

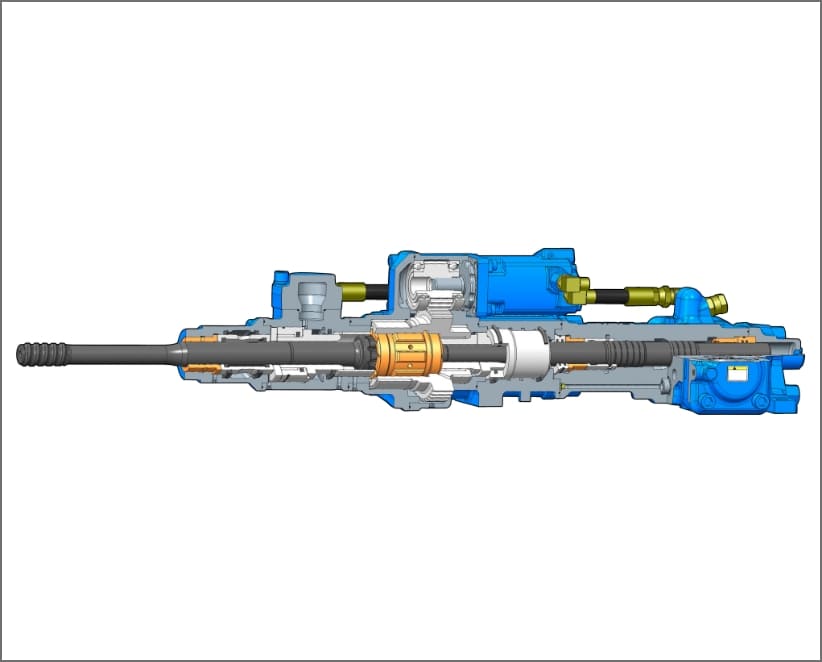

Drill Jumbo Drifter

This high-output hydraulic drifter achieves drilling with minimal hole deviation and roughness across rock types, from ultra-hard to soft rock. Specifically, by enhancing the efficiency and output of the striking mechanism through its proven dual damper system, it delivers best-in-class drilling performance and extended product life of bits, rods, etc. Enhanced durability of rotating components and a drifter mounting structure optimized for high-torque drilling enable stable, large-diameter drilling. The swivel seal system also helps improve maintenance.

Features

-

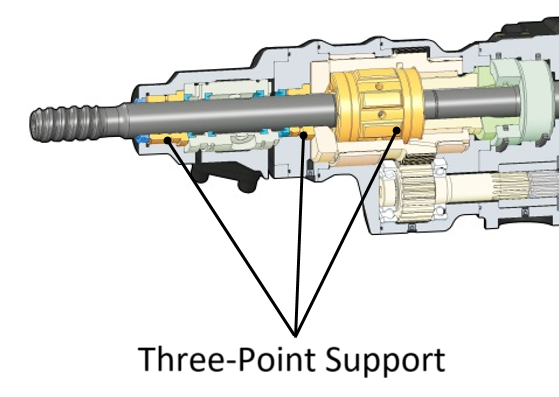

Stable Large-Diameter Drilling

Increased shank rod rigidity via three-point support enables handling of large-diameter drilling applications like forepoling and center cutting.

-

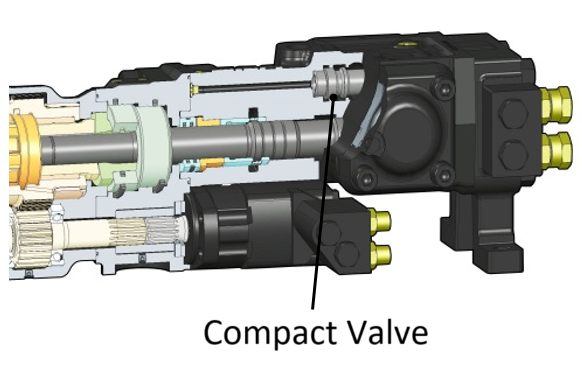

Dual Damper (Shock Absorption Device)

The dual damper enables drilling with optimal thrust, reducing idle blow and hole deviation while significantly extending the product life of accessories.

-

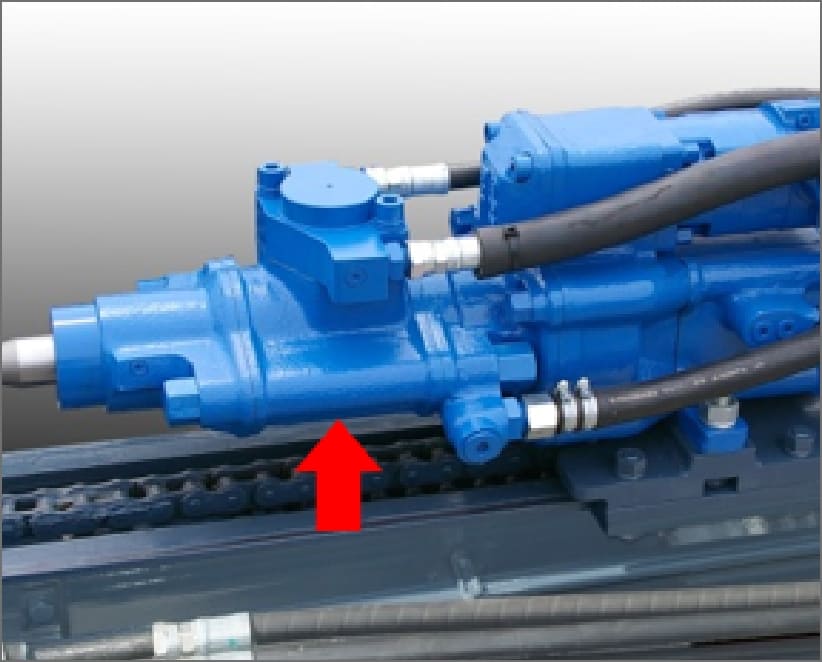

Compact Valve Design

The non-coaxial compact valve improves responsiveness and achieves high-efficiency impact output.